What are the best methods for preload in a bearing system?

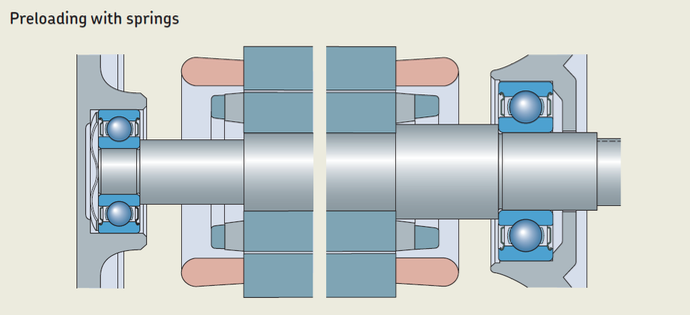

Springs

The simplest method of applying preload is to use a wave spring. The spring acts on the outer ring of one of the two bearings. This outer ring must be able to be axially displaced. In the diagram below, the bearing arrangement comprises a preloaded, single-row, deep groove ball bearing at each end of the shaft. The preload force remains practically constant, even when there is axial displacement of the bearing as a result of thermal elongation. The requisite preload force can be estimated using:F = k dwhere

The preload force remains practically constant, even when there is axial displacement of the bearing as a result of thermal elongation. The requisite preload force can be estimated using:F = k dwhereF = preload force [kN]

k = a factor, described in the following text

d = bearing bore diameter [mm]For small electric motors, values of between 0,005 and 0,01 are used for the factor k. If preload is used primarily to protect the bearing from the damage caused by external vibrations when stationary, then greater preload is required and k = 0,02 should be used.Spring loading is also a common method of applying preload to angular contact ball bearings in high-speed grinding spindles. The method is not suitable for bearing applications where a high degree of stiffness is required, where the direction of axial load changes or where indeterminate peak loads can occur.

Adjustment

Adjustment means setting the internal clearance or preload in an adjusted bearing arrangement during assembly. In operation, a certain clearance/preload —or only preload —range then arises. Axial preload in an adjusted bearing arrangement with single-row, angular, contact ball bearings, tapered roller bearings and deep-groove ball bearings is produced by displacing one bearing ring axially, relative to the other, by an amount corresponding to the desired preload force. There are basically two principal methods to adjust preload: individual adjustment and collective adjustment.a. Individual adjustment: With individual adjustment, each bearing arrangement is adjusted separately using nuts, shims, spacer sleeves, crush sleeves, etc. Measuring and inspection procedures are used to ensure that the established nominal preload is obtained with the least possible deviation. There are various methods to obtain the required preload:- axial displacement method

- frictional moment method

- direct force method

This method of adjustment is frequently used when the components of a bearing arrangement are preassembled. The required preload, which is expressed as a negative distance, requires measuring total axial positive displacement (end play) of the shaft relative to a fixed surface. This is typically done with a dial indicator. Shims, intermediate rings or spacers can then be used to adjust axial displacement to the correct negative distance. The width of the shims, intermediate rings or spacers is determined by:

This method of adjustment is frequently used when the components of a bearing arrangement are preassembled. The required preload, which is expressed as a negative distance, requires measuring total axial positive displacement (end play) of the shaft relative to a fixed surface. This is typically done with a dial indicator. Shims, intermediate rings or spacers can then be used to adjust axial displacement to the correct negative distance. The width of the shims, intermediate rings or spacers is determined by:- the distance between the shaft and housing shoulders

- the total width of both bearings

- the axial displacement corresponding to the desired preload force

- a correction factor for the axial displacement to account for thermal expansion in operation the manufacturing tolerances of all related components, established by measuring the actual dimensions before mounting

- a correction factor to account for a certain loss of preload as a result of settling and wear