ZZ Miniature Ball Bearing

Ball bearings are made of a variety of material types, including ceramic and metal. Ceramic ball bearings are generally recognized as superior because they can dissipate the heat and friction generated inside a ball bearing more easily than a normal metal ball bearing can. For purposes of normal...

ZZ Miniature Ball Bearing

ZZ Miniature Ball Bearing can be used for, space shuttle model motor, textile machinery, speed reducer, extruder, medical equipment, motors, printers, CPU cooling fan,glue machine, dairy machinery, vibrating sieve, fitness equipment, food equipment, robot, photo copier machine. Quick Details Brief Introduction:

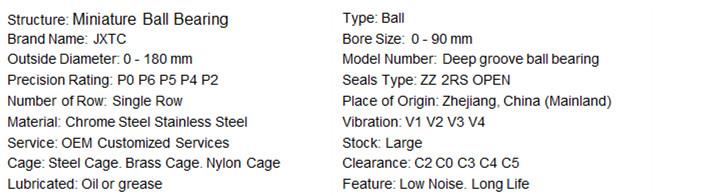

Brief Introduction:

Working Principle:

Ball bearings are made of a variety of material types, including ceramic and metal. Ceramic ball bearings are generally recognized as superior because they can dissipate the heat and friction generated inside a ball bearing more easily than a normal metal ball bearing can. For purposes of normal usage however, a 608 ball bearing typically consists of chrome steel balls, both for durability and economic reasons, as a ceramic ball bearing can be quite expensive. Keeping your bearing clean and lubricated will make it work better and last much longer.

Application:Deep Groove ball bearing can be used for CPU cooling fan, space shuttle model motor, textile machinery, speed reducer, extruder, medical equipment, motors, printers, glue machine, dairy machinery, vibrating sieve, fitness equipment, food equipment, robot, photo copier machine. Advantages:1.Low friction, almost noiseless and high rolling speed

2.Easy to install

3.Simple structure ensures fast equipment

4.Optimised internal design

5.High load ratings

6.Increased limiting speed

7.High strength ball guided brass cage

8.High dimensional and running accuracy

9.Narrow axial clearances or preloads range

10.Universal facing in standard

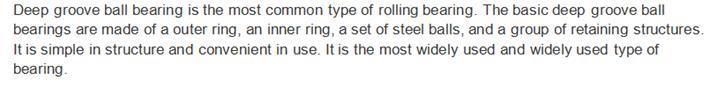

Data Sheet:

Products Show:

Production Department:

Customer Service:1. There is no replacement for courteous and efficient customer service. JXTC knows this, and provides experienced and well-trained personnel to assure a quick and reliable response for every customer. 2. From the initial greeting, through shipping and tracking orders, our customers can be sure if our attention to even the smallest details. You will get the right product to the right specs, shipped on-time, and at the agreed upon price. 3. Our staff is friendly, courteous, and above all, responsive. Your questions and quotes will be answered promptly, your transaction will be implemented efficiently, and your product will be shipped on time. 4. It is the policy of JXTC Bearings to provide product knowledge, application and engineering expertise, quality control, consistent and courteous customer service, and cost-efficient, high-quality products. FAQ:C:Does the sample fee can be return back?J: If you place an order, we can return part of sample fee even all of fee to you.It also depends on the Quantity of order and the type of sample.C: What causes bearing noise?J: Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.C: What is your terms of payment ?A: T/T advanceB: 30% T/T in advance .70% against copy of B/L (For large order)C: 50% in advance, the balance should be paid after seeing the picture of total goods.D: PaypalE: Western unionF: Official Bank Account Contact us:(Dongguan)Jiang Xin Technology Co.,LTDOffice: No.7 Shangfang Huanxi One Road, Zhouxi, Nancheng, Dongguan City, Guangdong Province, China.

Contact Person: Peggy Li

E-Mail: peggy@jxtcbearing.com / /info@jxtcbearing.com

Mobile/ Whatsapp/ Wechat: 0086-13559751737

Tel: 0086-769-89878157

0086-769-83078237-809

Fax: 0086-769-22280149Web:www.jxtcbearing.com