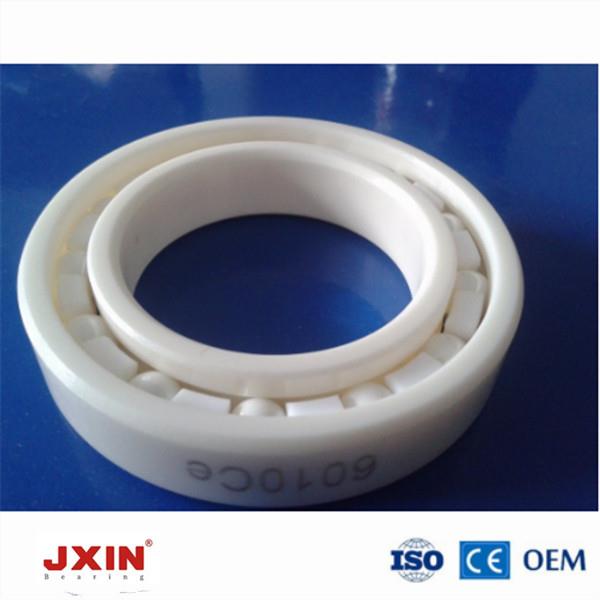

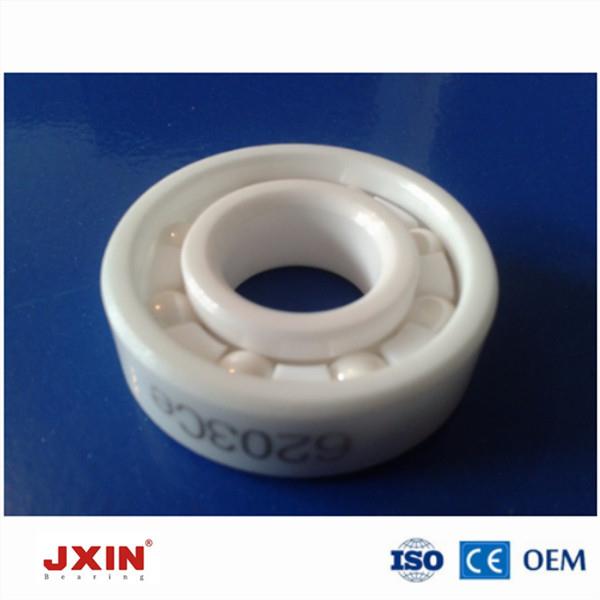

Ceramic Ball Bearing 6000, 6200,6300

Full ceramic bearings have the characteristics of anti-magnetic insulation, abrasion resistant, oil-free self-lubricating and enduring extreme high or low temperature, so they can be used for harsh environment and even under some special condition. The material of rings and roller is jar gonia...

Ceramic Ball Bearing 6000, 6200,6300

Ceramic ball bearing 6000, 6200,6300 can be widely used in skateboard, navigation, petroleum, ,automobile, electronics, power, textile, pumps, medical equipment and scientific research.

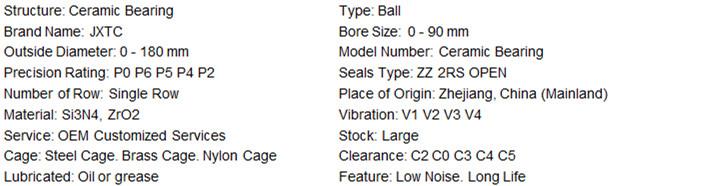

Quick Details

Brief Introduction:Full ceramic bearings have the characteristics of anti-magnetic insulation, abrasion resistant, oil-free self-lubricating and enduring extreme high or low temperature, so they can be used for harsh environment and even under some special condition. The material of rings and roller is jar gonia (ZrO2) and the holder uses poly back fluoride(PTFE) as standard configuration. Generally, we can use the reinforced nylon made of glass fiber 66(GRPA66-25), special engineering plastics(PEEK,PI),nonrust steel(AISI SUS316.SUS304), brass(Cu) and so on. ceramic deep groove ball bearings are made entirely of ceramic material and are superior to common Steel Angular Contact Bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM's, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present.

Featurer of ceramic bearing:High strength over a wide temperature range

High hardness

High fracture toughness

Outstanding wear resistance, both impingement and frictional modes

Excellent thermal shock resistance

Good chemical resistance

Superior chemical inertness

Application:Ceramic ball bearing 6000, 6200,6300 can be widely used in skateboard, navigation, petroleum, chemical industry, automobile, electronics, metallurgical, power, textile, pumps, medical equipment and scientific research. Advantages:1.Low friction, almost noiseless and high rolling speed

2.Easy to install

3.Simple structure ensures fast equipment

4.Optimised internal design

5.High load ratings

6.Increased limiting speed

7.High strength ball guided brass cage

8.High dimensional and running accuracy

9.Narrow axial clearances or preloads range

10.Universal facing in standard

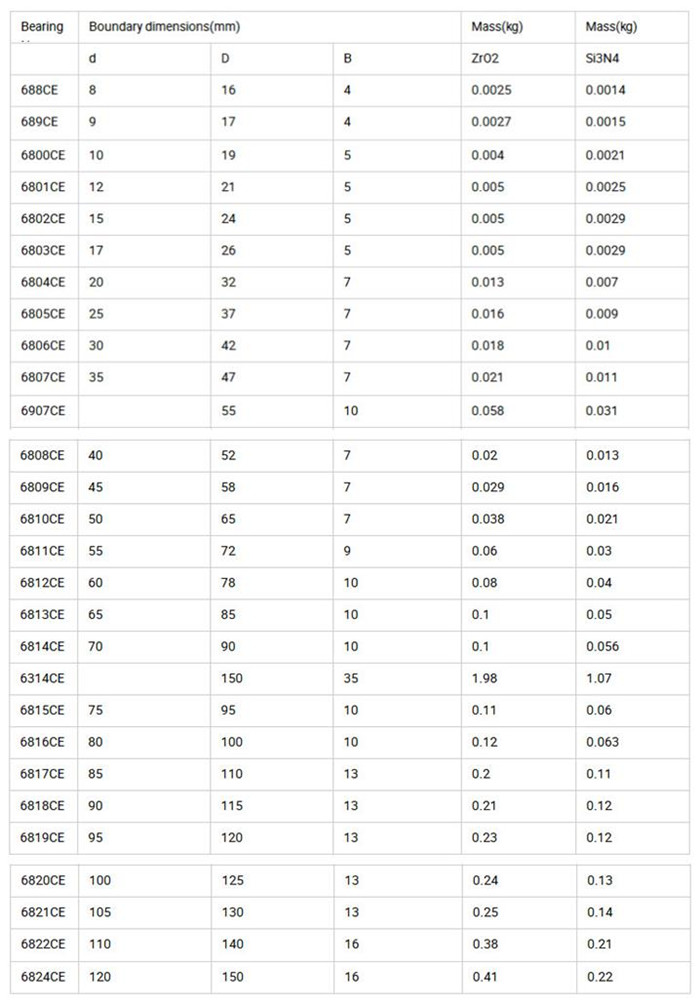

Data Sheet:

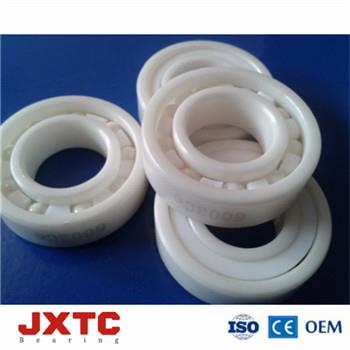

Products Show:

Production Department:

Customer Service:

1. There is no replacement for courteous and efficient customer service. JXTC knows this, and provides experienced and well-trained personnel to assure a quick and reliable response for every customer. 2. From the initial greeting, through shipping and tracking orders, our customers can be sure if our attention to even the smallest details. You will get the right product to the right specs, shipped on-time, and at the agreed upon price. 3. Our staff is friendly, courteous, and above all, responsive. Your questions and quotes will be answered promptly, your transaction will be implemented efficiently, and your product will be shipped on time. 4. It is the policy of JXTC Bearings to provide product knowledge, application and engineering expertise, quality control, consistent and courteous customer service, and cost-efficient, high-quality products. FAQ:C: Do you like accept small order bearing?J: we enjoy to grow up together with all our clients, whatever big or small, you will become bigger and bigger to be with us.C: How long is your delivery time?J: It is according to quantity. Generally it is 1-3 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,C: What causes bearing noise?J: Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.C: What is your terms of payment ?A: T/T advanceB: 30% T/T in advance .70% against copy of B/L (For large order)C: 50% in advance, the balance should be paid after seeing the picture of total goods.D: PaypalE: Western unionF: Official Bank Account Contact us:(Dongguan)Jiang Xin Technology Co.,LTDOffice: No.7 Shangfang Huanxi One Road, Zhouxi, Nancheng, Dongguan City, Guangdong Province, China.

Contact Person: Peggy Li

E-Mail: peggy@jxtcbearing.com / /info@jxtcbearing.com

Mobile/ Whatsapp/ Wechat: 0086-13559751737

Tel: 0086-769-89878157

0086-769-83078237-809

Fax: 0086-769-22280149Web:www.jxtcbearing.com